Sumo pfupi yegraphite electrode

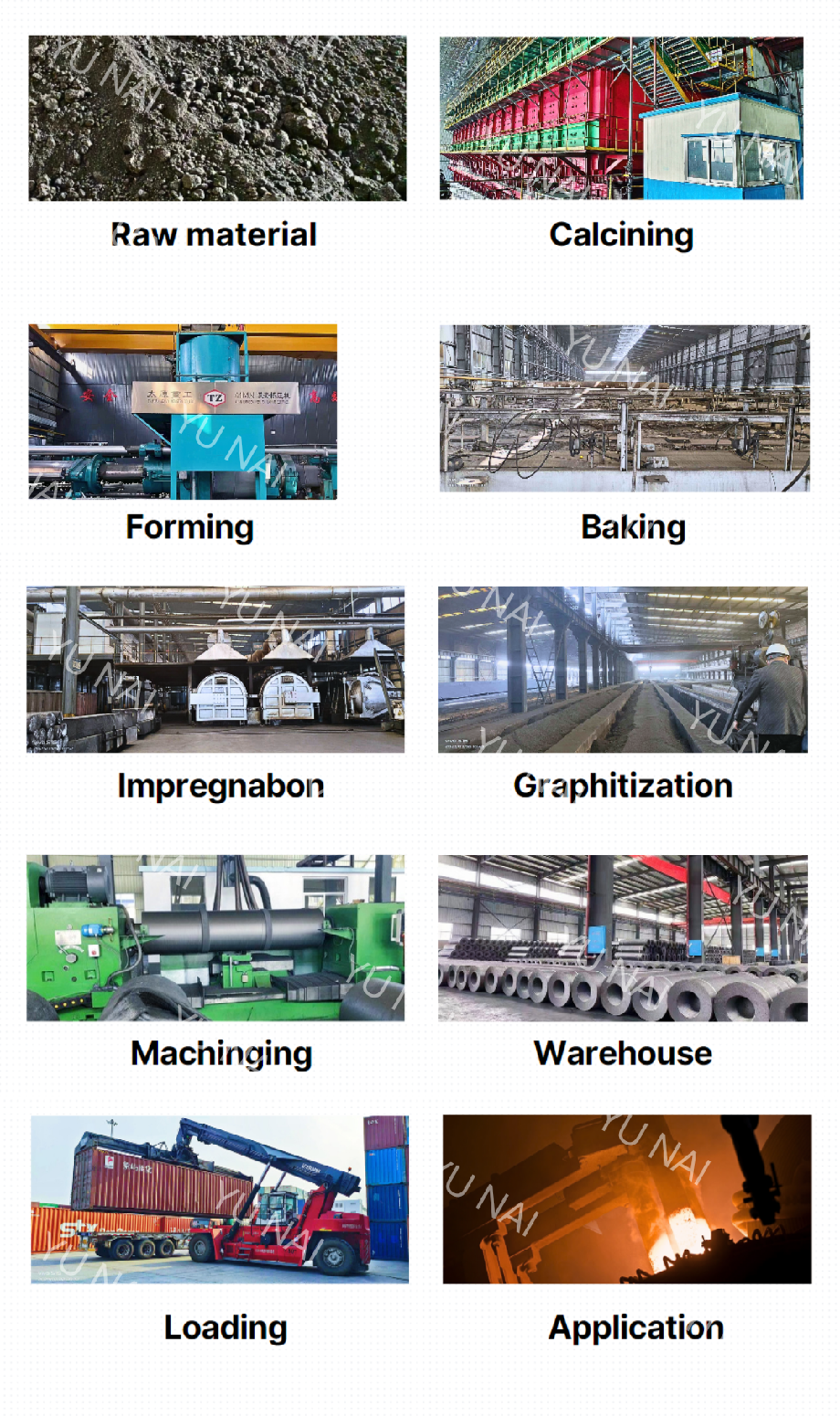

Graphite electrode inoreva petroleum coke, pitch coke as aggregate, marasha tar pitch sebinder, uye imhando yemagetsi isingachinjiki inogadzirwa nekuverengerwa kwezvinhu mbishi, kupwanya nekukuya, batching, kukanya, kuumba, kugocha, impregnation, graphitization uye mechanical. machining.Iyo yepamusoro tembiricha graphite conductive zvinhu inonzi artificial graphite electrode (inonzi graphite electrode)

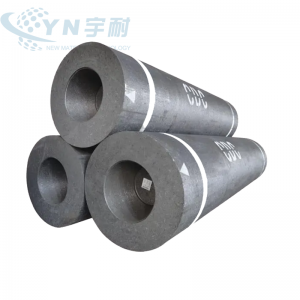

Graphite electrode classification

(1) Kazhinji simba graphite electrodes.Inotenderwa kushandisa magirafu emagetsi ane density yazvino yakaderera pane 17A/cm2, ayo anonyanya kushandiswa mune akajairwa magetsi emagetsi ekugadzira simbi, silicon kunyungudutsa, yero phosphorus kunyunguduka, nezvimwe.

(2) Anti-oxidation yakavharwa graphite electrode.Iyo graphite electrode yakavharwa ne-anti-oxidation inodzivirira layer inoumba danda rekudzivirira iro rinoita uye rinopesana nepamusoro-tembiricha oxidation, kuderedza kushandiswa kwe electrode panguva yekugadzira simbi.

(3) High-simba graphite electrodes.Graphite electrodes ane density ikozvino 18-25A / cm2 anobvumirwa, uye anonyanya kushandiswa mune yakakwirira-simba magetsi arc furnaces yekugadzira simbi.

(4) Ultra-yakakwirira simba graphite electrodes.Graphite electrodes ane density ikozvino yakakura kupfuura 25A/cm2 inobvumirwa.Inonyanya kushandiswa mu-ultra-high simba steelmaking yemagetsi arc furnace

Kugadzira maitiro e graphite electrode

Graphite electrode maitiro

1. High magetsi uye thermal conductivity;

2. High thermal vibration resistance uye kugadzikana kwemakemikari;;

3. Mafuta akanaka uye anogara kwenguva refu;

4, Chiri nyore kugadzirisa, yakakwira simbi yekubvisa uye yakaderera graphite kurasikirwa panguva yeEDM (spark yemagetsi)

5. Huremu chaihwo hwegraphite i1/5 yemhangura, uye graphite inorema 1/5 huremu hwemhangura muvhoriyamu imwe chete.Iyo electrode hombe yakagadzirwa nemhangura inorema zvakanyanya, izvo zvisina kunaka kurongeka kweEDM muchina chishandiso chinoruka panguva yenguva refu yemagetsi spark.Pane zvinopesana, graphite yakachengeteka kwazvo kubata.

6, Graphite ine yakakwira yekumhanyisa kumhanya iri 3-5 nguva nekukurumidza kupfuura simbi dzakajairwa.Uyezve, kusarudza akakodzera-kuoma maturusi uye graphite kunogona kuderedza kupera uye tearof cutter uye electrode.

Kungwarira pakushandisa graphite electrode

1.Paunenge uchishandisa kana kuchengetedza electrode, vashandisi vanofanira kuva nechokwadi chekudzivisa guruva remvura, kusvibiswa

uye kukonana.

2.Apo ma electrode anotakurwa nemarori eforklift, chiyero chavo chinofanira kuchengetwa kudzivirira

kutsvedza nekutyoka.Kudhumhana uye kuwandisa kunorambidzwa.

3.Ma electrodes anofanira kuchengetwa munzvimbo dzakachena uye dzakaoma.Kana yakachengetwa munzvimbo yakazaruka yekuchengetera,

anofanira kufukidzwa namatende.

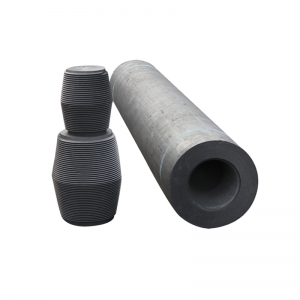

4. Kana uchibatanidza maelectrode, vashandisi vanofanirwa kutanga vashandisa mweya wakamanikidzwa kuchenesa tambo ye electrode, wobva watenderedza chinongedzo ichi kune imwe mugumo

Electrode hoist kune rumwe rutivi.Kudhumhana neshinda hakubvumidzwe.

5.Paunenge uchirova electrode, vashandisi vanofanira kushandisa hoko inotenderera ine nyoro yekutsigira pad pazasi pe electrode nipple kudzivirira kukanganisa pashinda.

6.Usati wabatanidza elecrodes, vashandisi vanofanira kuchenesa gomba nemhepo yakamanikidzwa.

7.Shandisa elastic hoist hoist kusimudza electrode kuchoto, ipapo tsvaga pakati uye fambisa electrode pasi zvishoma nezvishoma.

8.Apo iyo electrode yepamusoro yakaderedzwa 20-30mm kure ne electrode yakadzika, vashandisi vanofanira kushandisa mhepo yakamanikidzwa kuchenesa junction ye electrode.

9.Shandisa yakakosha torque spanet kuti usimbise electrode maererano nemirayiridzo, uye shandisa

mechanical, hydraulic yemhepo yekumanikidza midziyo yekusimbisa electrode kune yakagadziriswa torque.

10.Chibatiso che electrode chinofanira kuvharirwa mukati memitsara miviri michena yekudziya.The contact surface

pakati pemubati uye electrode inofanira kuva yakachena nguva dzose kuti urambe uchibata zvakanaka

iyo electrode, uye mvura inotonhorera yemubati inofanira kurambidzwa kubuda.

11.Kuvhara pamusoro pe electrode kuti usapinda oxidation uye guruva.

12.Kuitira kudzivirira kuputsika kwemagetsi, vashandisi havafanire kuisa zvivharo zvekudzivirira mukati

choto.Iko kushanda ikozvino kwe electrode kunofanira kuenderana nekushanda kunobvumirwa

ikozvino mubhuku rekushandisa.

13.Kudzivirira kuparara kwe electrode, isa zvinhu zvakawanda muchikamu chepasi uye chidimbu chidiki muchikamu chepamusoro.

Quote Now

Quote Now