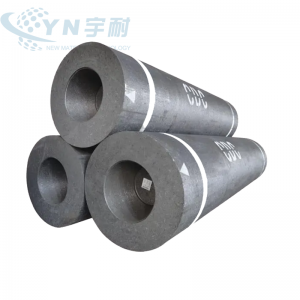

Ultra yakakwirira simba graphite electrode

Zvishandiso uye zvivakwa zve graphite electrodes:

1. Inoshandiswa mumagetsi arc steelmaking furnace

Graphite electrodes inonyanya kushandiswa mumagetsi echoto simbi.Electric furnace steelmaking ndeye kushandisa graphite electrodes kuunza ikozvino muchoto.Ikozvino yakasimba inopfuura nepakati pegasi pamucheto wezasi we electrodes kuti ibudise arc discharge, uye kupisa kunogadzirwa nearc kunoshandiswa pakunyungudutsa.Maererano nehuwandu hwevira remagetsi, magirafu emagetsi ane madhayamita akasiyana anoshandiswa.Kuti uite kuti magetsi ashandise nguva dzose, magetsi anobatanidzwa nemagetsi emagetsi akaiswa.Graphite maelectrodes ekugadzira simbi ane 70-80% yehuwandu hwehuwandu hwemagraphite electrodes.

2. Inoshandiswa muchoto chemagetsi chinopisa

Graphite electrode submerged thermal electric furnace inonyanya kushandiswa kugadzira ferroalloy, pure silicon, yellow phosphorus, matte uye calcium carbide, etc. Inoratidzirwa pakuti chikamu chepasi che electrode conductive chakavigwa mubhadharo, saka kuwedzera kune kupisa. inogadzirwa nearc pakati peplate yemagetsi uye mutero, Ikozvino Kupisa kunogadzirwawo nekupikiswa kwechaji kana ichipfuura nemubhadharo.Toni imwe neimwe yesilicon inoda kushandisa 150kg yemagraphite electrodes, uye toni yega yega yeyero phosphorous inoda kushandisa 40kg yemagraphite electrodes.

3. Inoshandiswa muvira rekudzivirira

Graphitization mavira ekugadzira zvigadzirwa zvegraphite, mavira ekunyungudusa ekunyungudusa magirazi, uye mavira emagetsi ekugadzira silicon carbide ese mavira ekupikisa.Zvishandiso zviri muchoto zvese zvinopisa zvinodzivirira uye zvinhu zvinopisa.Kazhinji, ma graphite electrodes ekuitisa anopinzwa mumadziro anopisa pamagumo echoto, kuitira kuti maelectrode ekuitisa haarambe achipedzwa.

4. Yekugadzirisa

Huwandu hukuru hwemagraphite electrode blanks anoshandiswawo kugadzira akasiyana akaumbwa zvigadzirwa senge macrucibles, mabhoti egraphite, anopisa anotsikirira mold uye zvinhu zvekudziya zvevacuum magetsi emagetsi.Izvo zvinofanirwa kucherechedzwa kuti kune marudzi matatu ezvigadzirwa zvekugadzira zvema graphite zvinhu pakupisa kwakanyanya, kusanganisira graphite electrodes, graphite molds uye graphite crucibles.Graphite mune izvi zvinhu zvitatu zvinowanzoitika kune oxidative combustion reactions pakupisa kwakanyanya, zvichikonzera kabhoni layer pamusoro pechinhu.Kuwedzera porosity uye yakasununguka chimiro kunokanganisa hupenyu hwebasa.

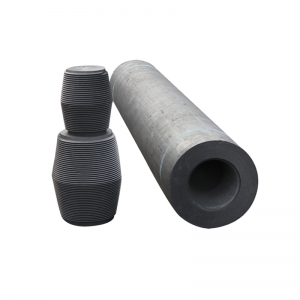

Graphite electrodes inonyanya kugadzirwa nepetroleum coke uye tsono coke, uye marasha tar pitch inoshandiswa sebhainda.Iwo anogadzirwa ne calcination, batching, kukanya, kudzvanya, kugocha, graphitization, uye machining.Vanosunungura simba remagetsi nenzira yema arcs mumagetsi arc furnaces.Makondukita ekudziya uye kunyungudutsa mutero anogona kukamurwa kuita akajairwa simba graphite electrode, yakakwirira simba graphite electrodes uye Ultra-yakakwirira simba graphite electrodes zvichienderana nemhando yavo zviratidzo.

Quote Now

Quote Now